WATERJET – Controlled, Precise Cutting…

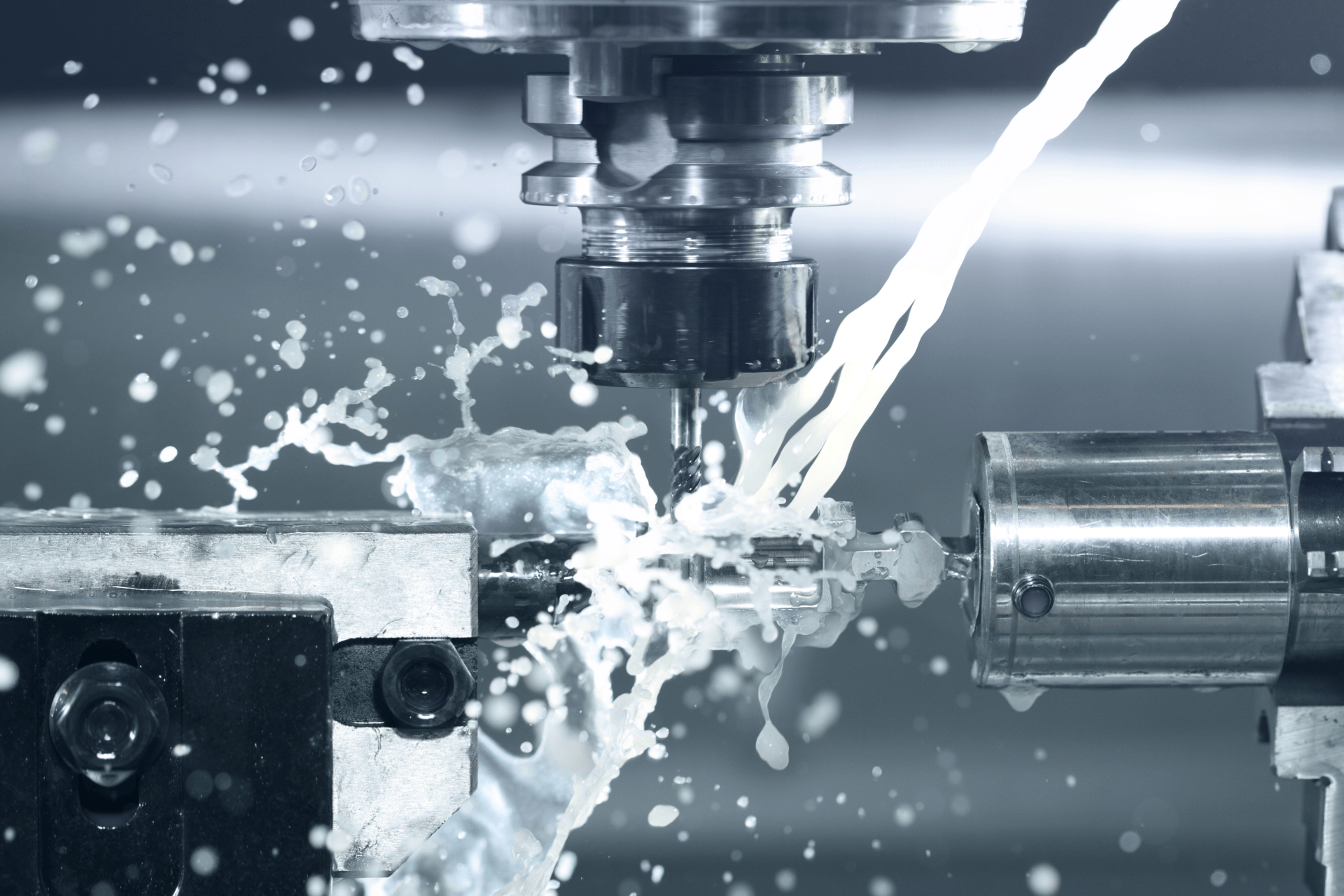

Our Bystronic Waterjet Cutting equipment uses a computer-controlled machine that is capable of cutting any sheet or plate material up to 200mm in thickness. Precise cutting is achieved by using an abrasive water jet, this cutting process uses an exceptionally high jet of water (3600BAR), that is mixed with garnet as an abrasive forming a fluid cutting tool.

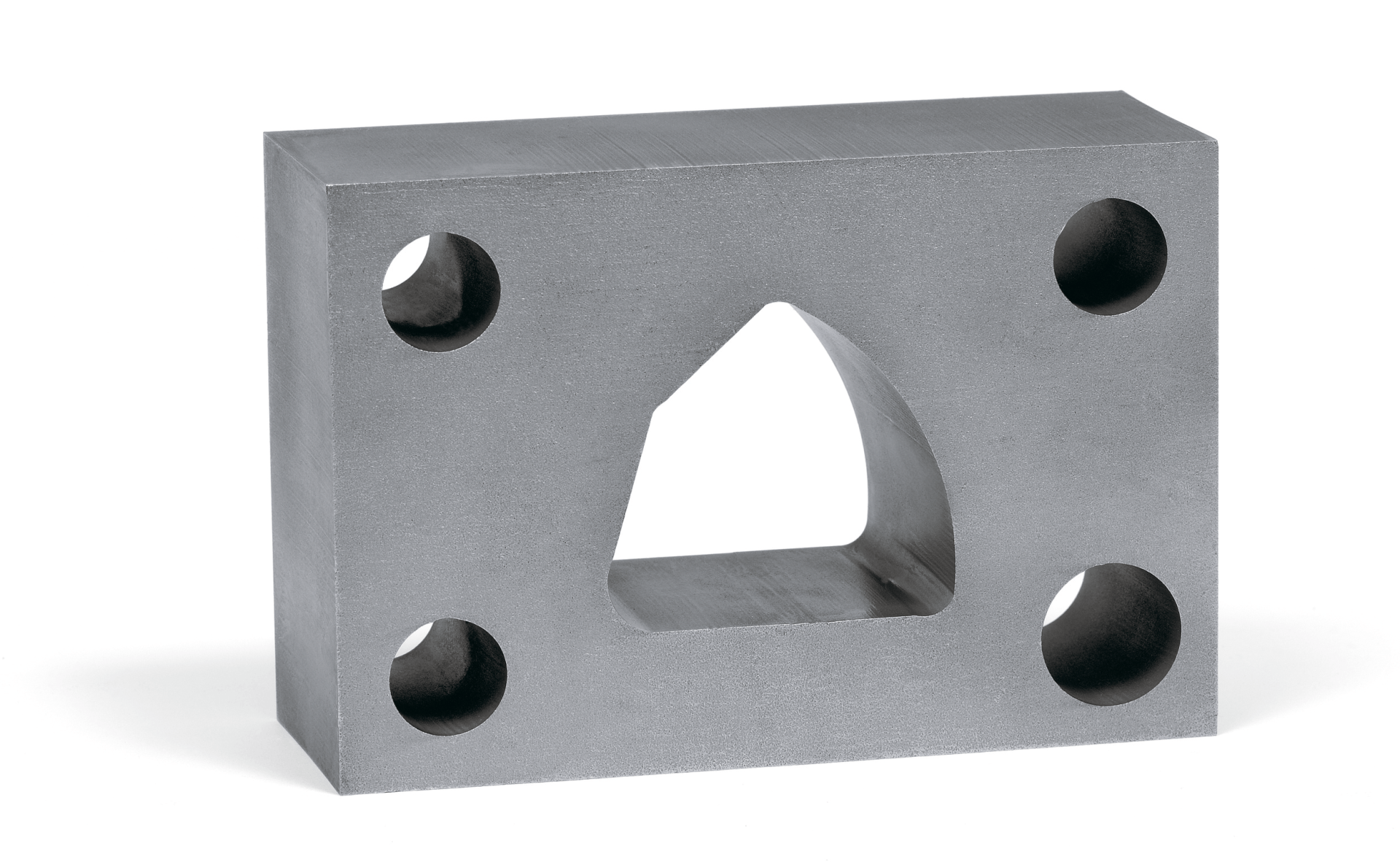

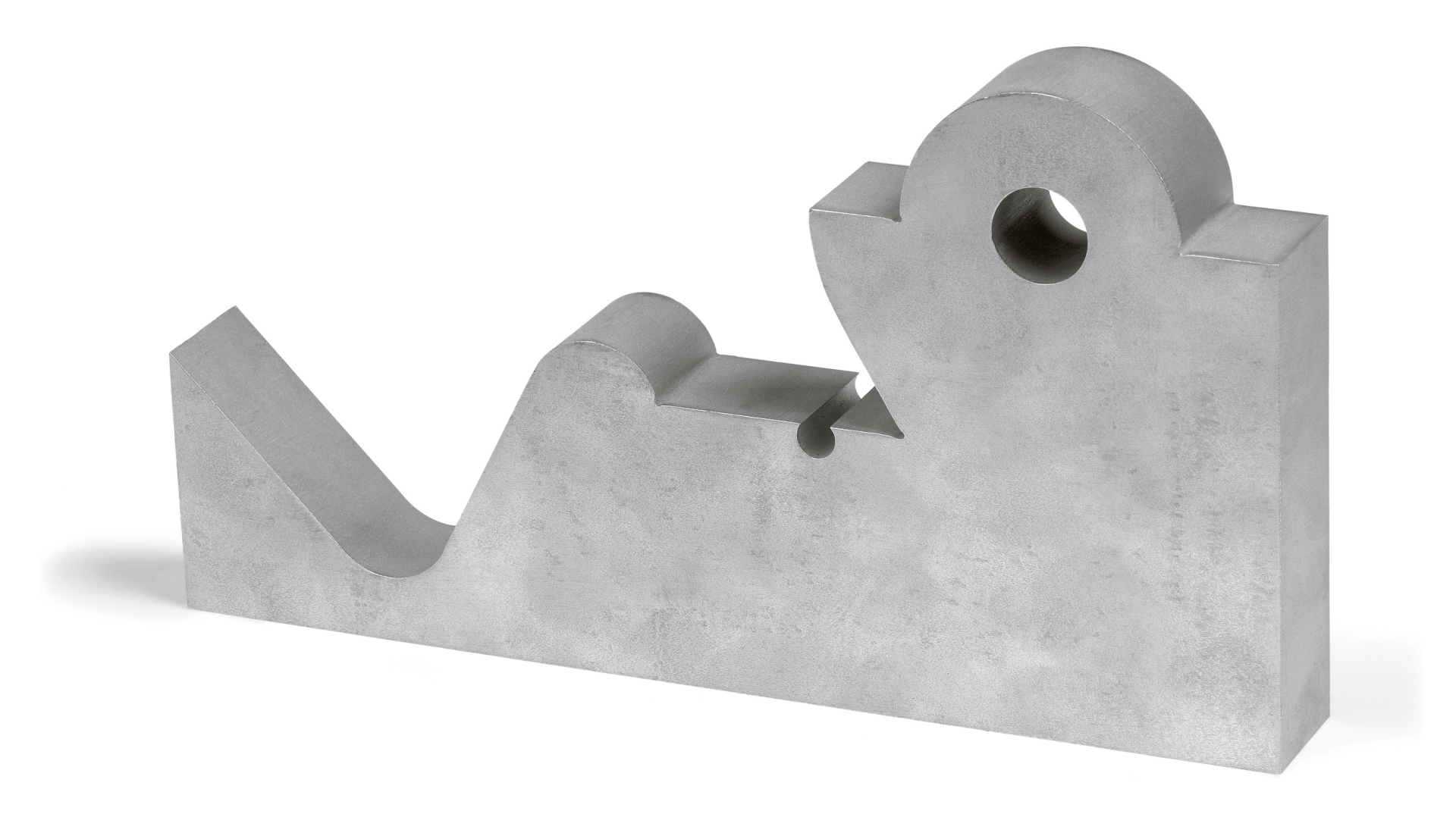

The pressurized mixture of water and garnet is forced through a tungsten carbide tube with an exit diameter of 0.75mm. This creates a forceful, accurate jet with a Mohs scale rating of 8, enabling an amazing degree of accuracy. The waterjet can cut detailed parts in materials from foam & plastics through to metals, carbon fibre, ceramics, and even armoured plate. This process is best described as “Accelerated Erosion”.

The main advantage of using Waterjet cutting is that it is a cold process – there is no heat application involved. Thermal processes such as Laser or Plasma cutting deforms the edges of cut composites and are evidently not suitable for some materials due to the combustion The micro-fine water jet is the most effective way of cutting complex shapes into materials.

The waterjet can cut the following materials:

Mild Steel

Stainless Steel

Aluminium

Rubber

Acrylic

Plastics

Cork

Carbon Fibre

Stone

Glass

Foam

Brick

Concrete Block

Marble

Polystyrene

Wood